TECHNOLOGY

Ground breaking high-performance prefabricated prefinished building’s along with integrated energy harvesting systems, using a set of standardised modular volumetric units (pods)

Technology

The use of eco-friendly and fully recyclable materials such as CO2 concrete (for floors) and steel, will be a necessary step towards adoption of the circular economy in the building industry and a step towards net-zero construction. These pod structures ca easily be demounted and recycled at the end of their life or at a time dictated by planning changes and calamities. In addition, the proposed technology offers greater advantages over existing prefabricated systems which are limited to lower rise buildings with limited configurations and built around a core.

Innovation

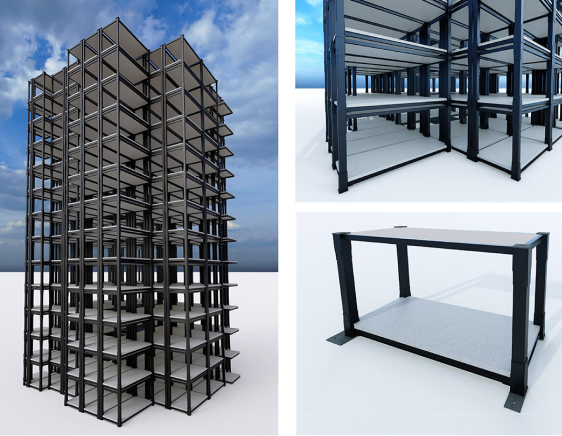

The innovative interconnection creates a moment resisting frame that can be used for the construction of multi-storey modular buildings up to 20 stories without the need for a structural core. It is estimated that eliminating the need for a structural core will minimise the use of concrete and etr-work on site.

PODS

The building blocks of the Pods are formed of prefabricated prefinished volumetric units manufactured in controlled conditions off site which are then transported to the build site and assembled using an innovative interconnection.

The Pods are characterised by lower over all weight, which makes transport more sustainable and cost effective.

Ease and speed of assembly with no site welding and innovative moment transferring connections.

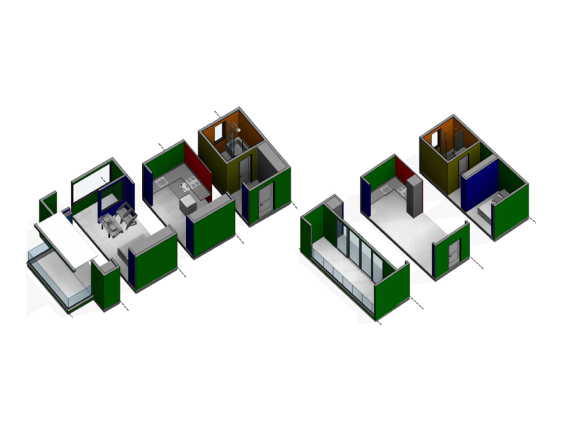

The ability to be configured in countless different arrangements on a floor plate.

Modular services all precision manufactured with a chain of custody certification.

Benefits

The build is based on advanced offisite manufacturing techniquese, supporting a Design of Manufacture and Assembly (DfMA) concept to significantly enhance the quality of build and produce efficient life cycle costs while reducing the following:

Time to build

Material wastage

Site pollution

Overall energy consumption in the manufacture and erection process

PHASE 1

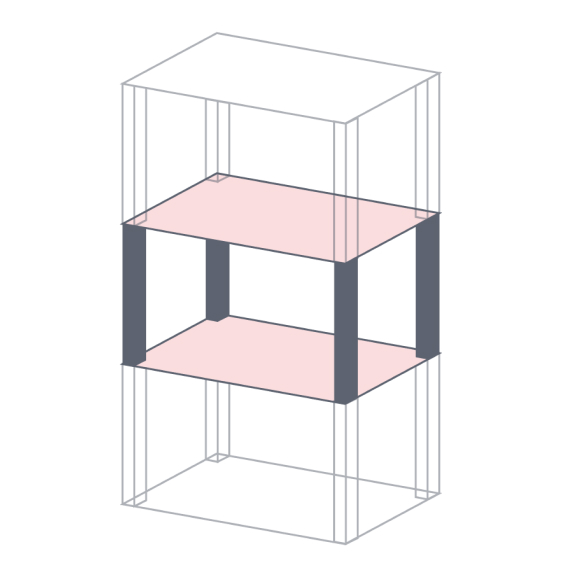

Development of new interconnection and standardised structural backbone

The innovative interconnection and modular structural backbone supports buildings of up to 20 stories, without the need for a structural core or any onsite concrete work

PHASE 2

Designed of high performance modular pods

The modular prefabricated prefinished volumetric pods are designed to easily assemble and create different designs. The use of low carbon material for construction, advanced manufacturing techniques for production, built in modular services, and energy efficient interior systems make it a high performance building system.

PHASE 3

Design of energy efficient modular facade and energy harvesting system

Innovative energy harvesting technology integrated into a new modular facade system both inside and outside ensures a highly energy efficient building envelope for the building and a source of energy for domestic use. As 80% of the cost of operating a building are typically attributable to environment comfort control and lighting, the combination of smart design tools for thermal facades and opportunities for onsite energy harvesting will help in reducing these costs.

PHASE 4

Smart energy management system and health monitoring

A computer-aided tool used by operators of electric utility grids to monitor, control and optimise performance, along with a self-powered structural health monitoring system integral in building maintenance. The health monitoring system is unique in that defects are identified at the time of occurrence rather than waiting for visual cues which can be dangerous. Working in real time is safe and secure for infrastructure maintenance and longevity.

PHASE 5

Life cycle and carbon emission assessment

A comprehensive program for assessing the green rating performance of the high performance modular building systems, leading to a smart zero carbon building, while minimising construction waste.